SLLA562 May 2021 ISOW1044

1 Application Brief

Controller Area Network

The Controller Area Network (CAN) protocol is popular in power delivery, grid infrastructure, motor drives, factory and building automation applications due to its arbitration and prioritization features. Since many of these applications feature multiple voltage domains, galvanic isolation is needed along the signal path in these CAN networks. Engineers can isolate their CAN signals through devices with integrated isolated CAN transceivers or with a discrete digital isolator placed next to the CAN transceiver, which provides the necessary protection of the low voltage circuitry from the high voltage side. These devices also improve noise immunity and ensure reliable communication between the CAN nodes on the different voltage domains.

However, isolating the signal path is only one challenge associated with communicating across different voltage levels. Isolators and isolated CAN transceivers require isolated power supplies to function properly. In some limited instances, both sides of the isolating device can be powered directly from the system power supply that exists in the two domains. More commonly, however, the isolated CAN transceivers from one board are likely communicating with a transceiver on a distant board, and hence the need to provide a local isolated power supply becomes inevitable.

This application brief shares the different options to isolate signal and power in isolated CAN systems. Figure 1-1 shows four different isolated CAN nodes. Moving from node 1 to node 4, each solution has different level of integration. Node 1 has a complete discrete solution with the discrete isolator in series with a CAN transceiver, while the transformer driver provides the excitation for the external transformer to provide the isolated power supply (VISO1). Node 2 uses a similar isolated power supply but shows the integrated isolated CAN devices that save some board space.

Figure 1-1 Interconnected CAN Nodes with

Different Isolated Signal And Power Configurations

Figure 1-1 Interconnected CAN Nodes with

Different Isolated Signal And Power ConfigurationsNode 3 uses an isolated data and power device (ISOW7741) to eliminate the digital isolator and the isolated power discrete components from node 1. The external CAN transceiver in series allows for CAN communication. Finally, Node 4 integrates the CAN transceiver in the isolated data and power device to further simplify the design.

The discrete solutions used for Node 1 and Node 2 do have their advantages. The efficiency of power transfer is around 90% and the radiated emissions are relatively lower due to the lower switching frequency of the transformer drivers (150kHz to 420kHz). The flexibility of choosing any CAN transceiver to meet the system requirements allows Nodes 1 and 3 to be unique. But there are several reasons why the completed integrated solution of Node 4 still receives the approval from many designers.

- Simplicity of design: Isolation has steadily grown as more and more systems are being driven at higher voltages and need to communicate across multiple voltage domains . The addition of isolation and isolated power complicates the design process for signal chain designers, who traditionally did not have to worry about power supply design. For example, the designers need to use the right power control topologies, choose the size and cost-effective transformers, and also take care of the routing parasitic to achieve optimum emission and efficiency. By providing a single-chip solution such as the ISOW1044, designers can streamline the transformer selection process during design.

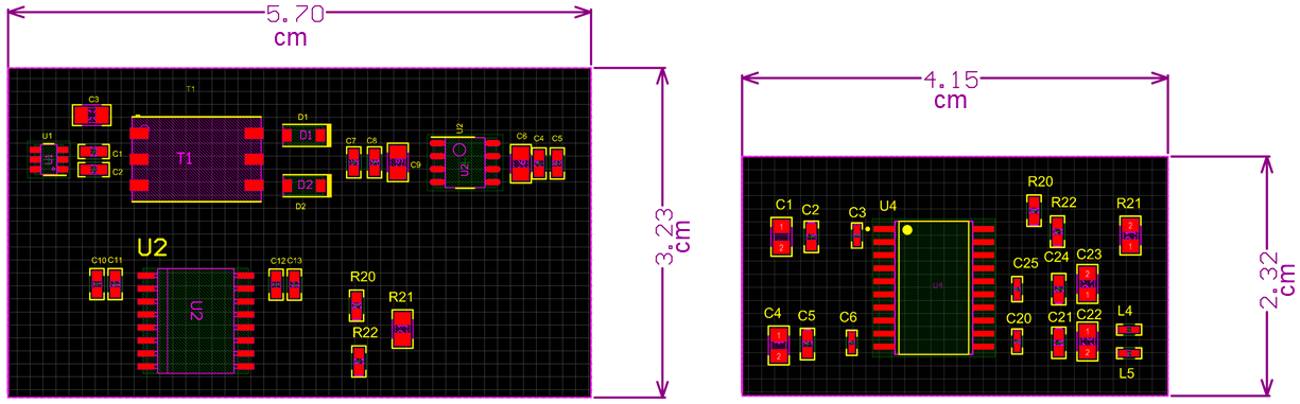

- Compact design and lower cost: Transformers or modules used for isolated power typically occupy a large space on the board, not only in the X and Y dimension but also in height. For applications where the boards are stacked next to each other this transformer height often dictates the spacing between boards. By using planar transformers within the standard SOIC package, the ISOW1044 reduces board space by almost 48% when compared to discrete solution, like in Node 1 or 2 in Figure 1-1. Figure 1-2 compares the board space occupied by Node 2 configuration versus Node 4.

Figure 1-2 Board Spaces Comparison of Discrete and Integrated Solution

Figure 1-2 Board Spaces Comparison of Discrete and Integrated Solution- Reliability: The transformer height which is normally two to three times the height of the packaged solution almost acts as high rise building as compared to the other devices in its vicinity. With any vibration in the system, the transformer is more likely to get affected as compared to a shorter single-chip solution. Additionally, the part-to-part variation of transformers are usually larger and therefore less preferable for designs which require tight process control and high accuracy.

- Ease of certifications: Different regions have different requirements for standards such as VDE, UL, CSA, TUV. Discrete solutions put the onus of finding the right transformer on the designers. The integrated solutions such as the ISOW7741 or ISOW1044 are certified by these agencies, thereby speeding up the design and time to market.

Performance Trade-off

Integrating the planar transformer in a package comes with its challenges. The driver circuit, transformer and the receiver all need to be matched well so there is no common mode noise produced by the isolated power circuitry. In addition, since the size of the transformers needs to be kept small, this drives the switching frequencies to be limited in the MHz range. The faster switching frequency causes more noise in the system.

TI Solution

TI’s isolated CAN transceiver, the ISOW1044, uses a symmetric architecture of the isolated power design to improve the emissions performance of these devices over competing solutions. Figure 1-3 shows the test setup of the ISOW1044 radiated emissions. A battery voltage source was used with a low-dropout regulator (LDO) to generate the 5-V power supply for the ISOW1044 on an evaluation module. Ferrite beads were used for the testing before and after the LDO and also between the output of the ISOW1044 and ground to suppress high amplitude spikes in the emissions spectrum.

Figure 1-3 ISOW1044 Radiated Emissions

Test Setup

Figure 1-3 ISOW1044 Radiated Emissions

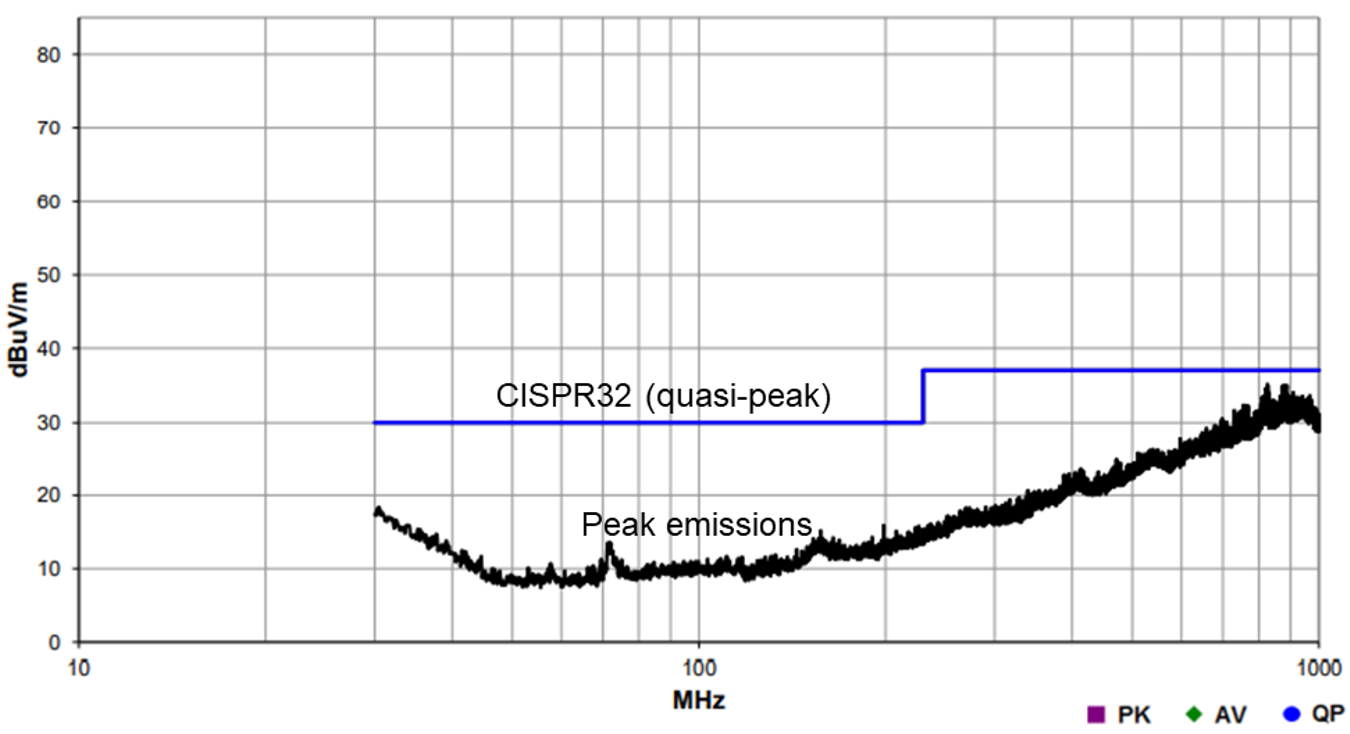

Test Setup Figure 1-4 shows the ISOW1044 passing the CISPRS32 class B standard limits on a two-layer PCB without any stitching capacitors, Y-capacitors or common mode choke (CMC) at the CAN data-rate of 1 Mbps.

Figure 1-4 ISOW1044 Radiated Emissions at

1-Mbps Data Rate

Figure 1-4 ISOW1044 Radiated Emissions at

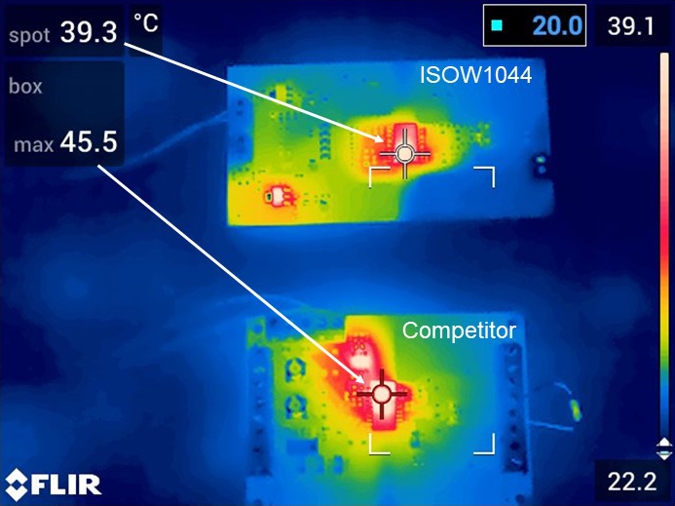

1-Mbps Data RatePacking multiple die inside a single chip does add the challenge of thermal performance of the integrated device. The ISOW1044 and a competing device were both tested under the same conditions at CAN with Flexible Data Rate (FD) speed of 5 Mbps and the thermal images were captured by a thermal gun. The results shown in Figure 1-5 where the top image refers to the ISOW1044 and has a maximum temperature of 39.3 °C. A competing device is also shown in Figure 1-5 and is running 6.2°C hotter than the ISOW1044. 47% efficiency of the ISOW1044 enables lower power dissipation and extends the ambient temperature range support from -40C to 125C.

Figure 1-5 Thermal Performance of

ISOW1044 and Competing Device

Figure 1-5 Thermal Performance of

ISOW1044 and Competing DeviceISOW1044 Additional Features

Fully integrated ISOW1044 guarantees the CAN FD timing specs up to 5 Mbps in one single data sheet, eliminating uncertainty caused by stringing together multiple components. ISOW1044 also features extended bus fault protection of up to +/-58V, providing extra margin to protect against accidental CAN bus shorts to power supplies. In addition, the integrated 10 Mbps GPIO channel can be used for additional system-level signal isolation eliminating the potential need for additional opto-coupler or digital isolator. ISOW1044 can operate from a single 5 V supply or have the option to use a separate logic supply that can go down to 1.8 V.

Conclusion

TI’s isolated CAN transceiver with integrated DC-DC converter, ISOW1044, provides a compact solution as compared to discrete solution available in the market. The device passes the CISPR32 class B radiated emissions and is highly efficient to enable operation over the entire industrial temperature range.